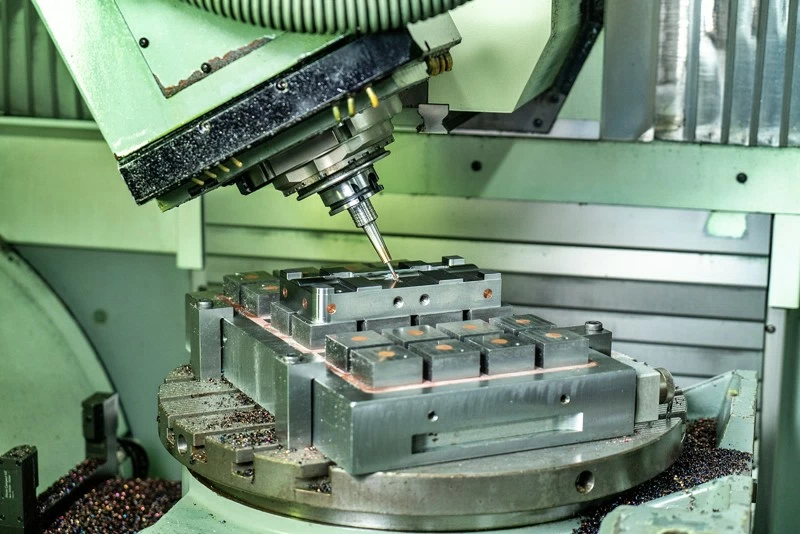

In-House Tooling Shop

At the core of YOMURA TECHNOLOGIES' injection molding process lies our advanced tooling capabilities.

Contact UsAutomated Tooling Fabrication

Connectivity

Integrated processes with minimal manual input errors.

RFID Implementation

Reducing errors with embedded RFID chips on each workpiece.

Quality Assurance

2D and 3D measurements for 100% accuracy requirements.

Pre-set 2D to locate the center point, and to calibrate the work piece before process start

Load the work piece one bye one

visual check to ensure the work pieces are in correct location before pushed in the base plate

push in the base plate

Close door with both hands

Door closed / Blue light on

Robotic arm moves the work piece to CNC working station

Machine the work piece to the setting spec

Rotate 90 degrees to pour out eh lubriant before return to storage

Use CMM to calibrate the differential then transfer the data back to the working station (CNC or EDM)

V Accurate → Manufactureing

X Verifiation → Return to Step 1

Productivity and Efficiency

50%

Productivity Increase

Expected growth in tooling fabrication efficiency monthly.

24/7

Continuous Operation

Automated system operates round the clock for efficient fabrication.

Technology Integration

Automation

Integrated and automated manufacturing for precision and efficiency.

Quality Control

Meticulous standards ensuring high-quality tooling production.

Efficiency

Efficient production processes for optimal tooling solutions.

Industry Leadership

Expertise

Deep knowledge and experience in advanced tooling technologies and processes.

Innovation

Continuous innovation and commitment to cutting-edge tooling solutions.

Industry Recognition

Established reputation as leaders in the manufacturing and tooling industry.

Contact Us