Yomura's

3Q Verification Excellence

A comprehensive approach to ensuring

unparalleled medical device quality and safety.

What is 3Q ?

3Q stands for "Three Qualifications" which represent the three qualifying tests required for ensuring the reliability and performance of a piece of equipment or technology. These tests include Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ).

IQ, Foundation of Assurance

Installation Qualification

Yomura's rigorous Installation Qualification forms the bedrock of our 3Q verification, encompassing meticulous inspections, precise calibrations, and exhaustive documentation to confirm every aspect of our medical devices are operationally ready.

Comprehensive Inspections

Yomura's rigorous Installation Qualification forms the bedrock of our 3Q verification, encompassing meticulous inspections, precise calibrations, and exhaustive documentation to confirm every aspect of our medical devices are operationally ready.

Calibration Certainty

Our highly-skilled technicians ensure that each component functions correctly through consistent calibration and cross-referencing with manufacturer standards to establish total system readiness.

OQ, Performance Safeguards

Parameter Assessment

We subject our devices to extensive testing across all operational conditions, meticulously assessing variables like heat, pressure and timing, ensuring every performance criterion is met or exceeded.

Process Simulation

OQ simulation exercises test the devices' endurance, exposing them to the demands of actual usage scenarios to validate real-world reliability and efficacy.

Acceptance Framework

By establishing a detailed framework of predefined acceptance criteria, we leave no room for ambiguity in our pursuit of quality—each operational facet is verified against stringent thresholds.

PQ, Confirming Consistency

Production Runs

Yomura's PQ stage involves extensive production cycles, underpinning our steadfast commitment to manufacturing devices that are not just compliant but consistently excel in quality benchmarks.

Data-Driven Analysis

We collect, scrutinize, and analyze large volumes of production data, enabling precise and proactive quality control that is deeply informed by empirical evidence.

Regulatory Rigor

Aligning with global standards, our PQ process confirms that every device meets the most exacting quality specifications and regulatory imperatives, instilling deep trust in our manufacturing excellence.

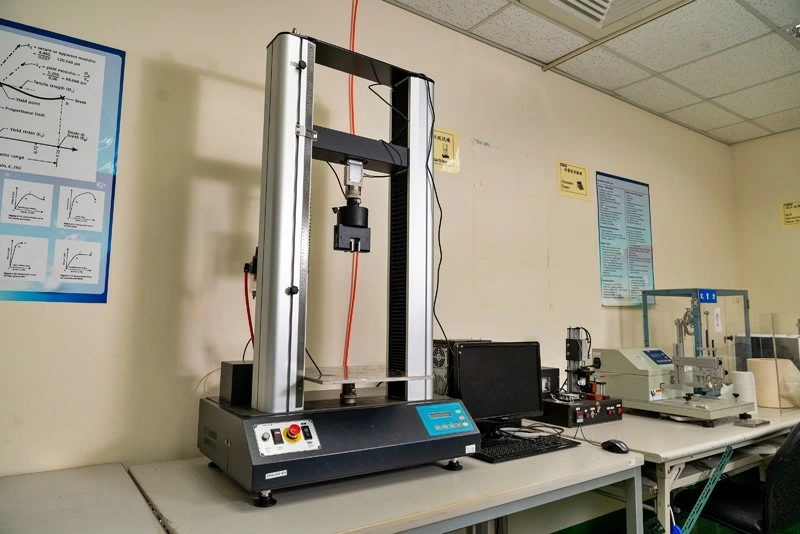

Advanced QC Equipment Investment

Metrology Mastery

We harness the precision of advanced metrology tools to measure and ensure the utmost accuracy within every component of our medical devices.

Vision Inspection Innovations

State-of-the-art visual inspection systems provide an additional layer of scrutiny, capturing minute details unseen by the naked eye to reinforce our impeccable quality standards.

Testing Equipment Excellence

Meticulously maintained and calibrated testing apparatus ensures that each device undergoes a thorough evaluation to withstand the highest demands of performance.

Scientific Molding for Optimal Outcomes

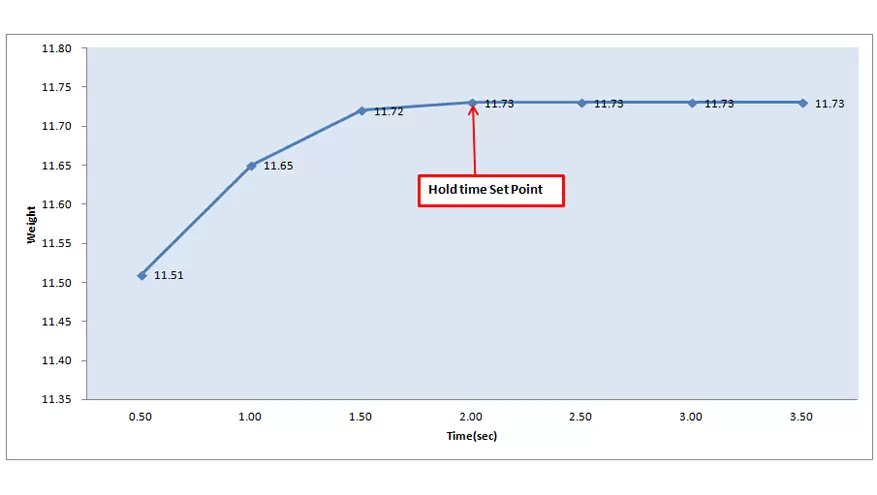

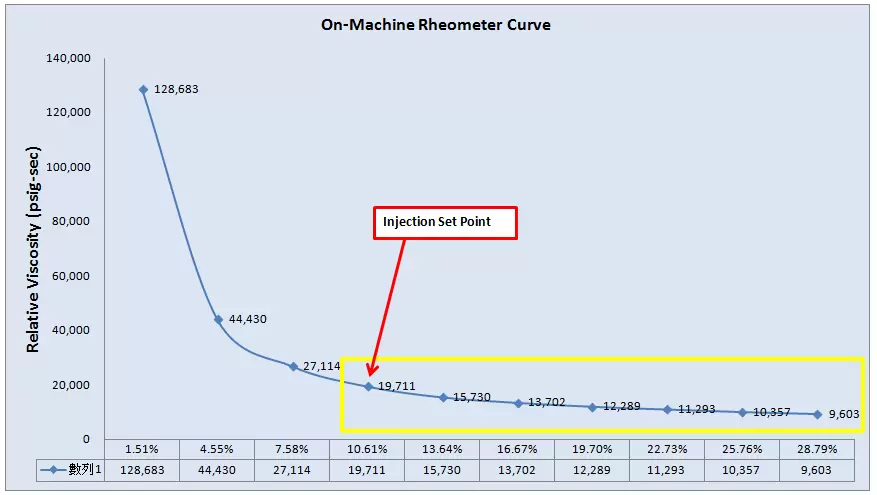

Process Monitoring

Intensively meticulous monitoring of the manufacturing environment and variables ensures predictability and consistency in production.

Data Analysis

Data is the nucleus of decision-making. Our rigorous analysis enables us to understand and eliminate process variations that could compromise quality.

Statistical Control

Employing statistical tools, we forecast, adapt, and continuously refine our processes for unerring precision and superior product outcomes.

Ongoing Commitment to Excellence

1

Continuous Improvements

Our relentless pursuit of excellence means never resting on laurels; instead we monitor, analyze, and improve our processes continuously.

365

Annual Audits

We subject our entire operation to rigorous audits yearly, ensuring enduring adherence to the highest quality and safety standards.

100%

Total Satisfaction

Our ultimate goal is the complete satisfaction of our clients and the health and safety of end-users, achieved through unwavering diligence in quality.