Innovative In-Mold Decoration Solutions

YOMURA TECHNOLOGIES leads with cutting-edge IMD and IML techniques for high-quality plastic components.

CONTACT USWhat is In-Mold Decoration (IMD)?

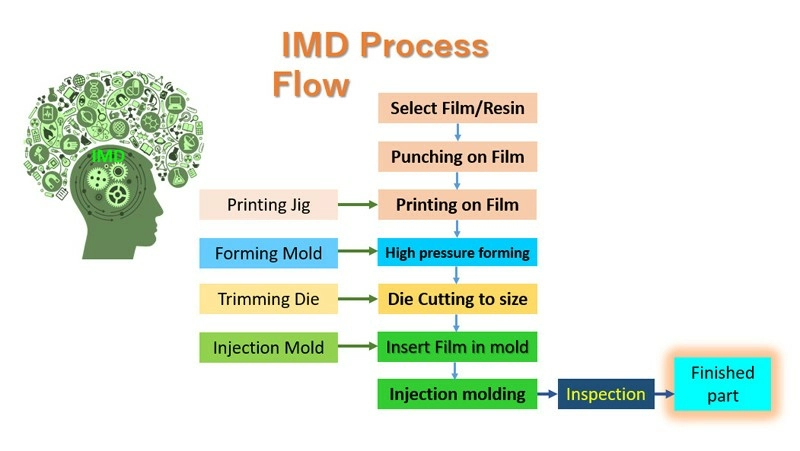

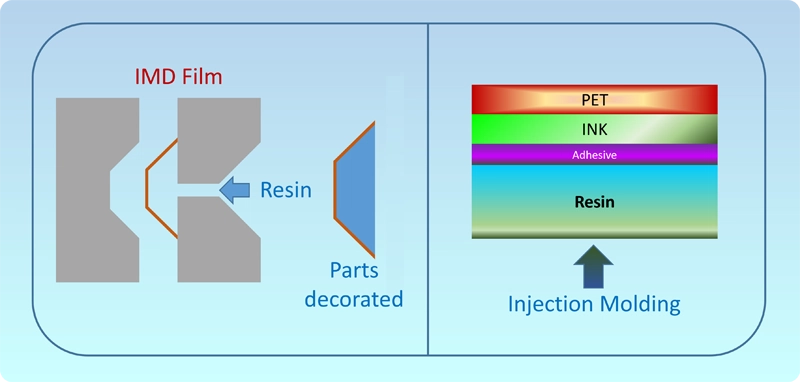

In-Mold Decoration (IMD) is a specialized injection molding process that combines decorative elements, such as films, foils, or inserts, with the molding of plastic components. It offers several advantages over traditional decoration methods:

Durability

The decorative elements are bonded directly to the plastic substrate, providing superior resistance to wear, scratches, and environmental factors.

Design Flexibility

IMD enables the creation of intricate designs, textures, and patterns that would be challenging or impossible to achieve through conventional decoration methods.

Cost-effectiveness

By eliminating secondary decoration processes, IMD streamlines production and reduces overall manufacturing costs.

In-Mold Labeling (IML)

In-Mold Labeling, or IML, is a variation of the IMD process that involves the integration of pre-printed labels or graphics directly into the plastic component during the injection molding cycle. This technique provides a highly durable and aesthetically appealing solution for product identification, branding, and labeling applications.

Permanent Labeling

The labels are firmly bonded to the plastic substrate, ensuring long-lasting durability and resistance to peeling or fading.

High-Quality Graphics

IML allows for the use of high-resolution graphics, enabling vibrant and detailed product branding and labeling.

Efficient Production

By combining the labeling process with injection molding, IML eliminates the need for separate labeling operations, streamlining production and reducing costs.

Advanced IMD/IML Capabilities

At Yomura, we have invested in state-of-the-art IMD and IML equipment and technology to deliver exceptional results. Our capabilities include:

Automated Handling and Placement

With our advanced IMD/IML capabilities, we are able to automate the handling and placement of decorative elements during the injection molding process. This ensures precise application of labels or graphics, enhancing the overall aesthetic of the product. Additionally, our equipment and technology enable us to efficiently produce high-quality IMD/IML components at a faster rate, further optimizing the manufacturing process.

Advanced Mold Design

Our team utilizes advanced mold design and simulation software, allowing us to create intricate and precise molds for the IMD/IML process. This software enables us to simulate the injection molding process, identifying any potential issues or improvements before production begins. Through this innovative technology, we can ensure the highest level of quality and efficiency in our mold designs.

In-House Mold Manufacturing

Our in-house mold manufacturing and maintenance capabilities give us full control over the production process, allowing for quicker turnaround times and prompt maintenance when needed. With our dedicated team of experts and state-of-the-art equipment, we can ensure that molds are manufactured to the highest standards and maintained in optimal condition for consistent and reliable performance. This level of control and expertise in mold manufacturing and maintenance directly contributes to the overall efficiency and quality of our IMD/IML components.

Cleanroom (ISO Class 7)

Our cleanroom manufacturing facilities (ISO Class 7) further ensure the quality and precision of our IMD/IML components. These controlled environments reduce the risk of contamination and help maintain consistent production conditions. Additionally, our team undergoes rigorous training to maintain the proper protocol required in cleanroom manufacturing.

Stringent Quality Control

To ensure that our IMD/IML components meet the highest quality standards, we have implemented stringent quality control and inspection procedures. Our team carefully inspects each step of the mold manufacturing process to identify and address any potential defects or issues. In addition, we perform thorough testing and inspection of finished components to guarantee their performance and reliability.

Industry Applications

Consumer Electronics

IMD/IML for innovative tech aesthetics.

Automotive

Durable components for vehicle interiors.

Medical

High-quality plastic parts for medical devices.

Others

Appliance, aerospace, and telecommunications.

Partner with YOMURA

Discuss Requirements

Start with a conversation about your project.

Design Optimization

Our team collaborates to refine your design.

Bring Ideas to Life

See your concepts realized with our expertise.