Insert-Molding: Integrating

Materials for Enhanced Performance

Explore the possibilities with Yomura's Insert Injection Molding technology - seamlessly integrating metal, plastic, or ceramic inserts into plastic components for improved structural integrity and enhanced functionality. Contact us today to unlock new possibilities for your products.

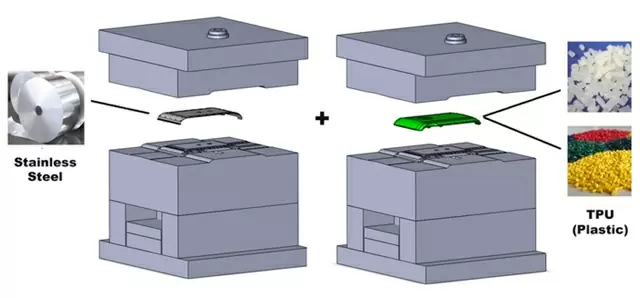

CONTACT USThe Insert Molding Process

Insert Placement

The process begins by placing the desired insert, such as metal, plastic, or ceramic, into the mold cavity.

Plastic Injection

A carefully selected plastic material is injected directly over the insert, encapsulating it within the molded component.

Unified Integration

The result is a single, unified part with the insert securely embedded within the plastic matrix, creating a seamless integration.

A Wide Range of Materials

Engineering Plastics

Offering improved wear resistance, tensile strength, and weight reduction.

more...

- TPR + Metal Frame(3C Mechanical Parts)

- ABS + Al. Die Cast (Sports/ Medical) Eng.

- Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector)

- Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

Thermoplastic Rubbers (TPRs)

Provide enhanced flexibility and durability, ideal for specific applications.

Applications of Insert Molding

Consumer Electronics

Integrating metal frames, plated copper pins, and sockets for enhanced durability and improved electrical connectivity.

Automotive

Combining metal die-cast inserts with plastics for lightweight, high-strength structural components.

Sports and Medical

Embedding metal or ceramic inserts into plastic components for enhanced performance and durability.

Electrical and Electronics

Encapsulating wire frames, copper pins, and contacts into plastic components for precise electrical connections and insulation.

Benefits of Insert Molding

Reduced Assembly and Labor Costs

Integration of multiple components minimizes the need for separate assembly processes, lowering costs and improving efficiency.

Increased Design Flexibility

Allows for virtually unlimited configurations, enabling complex geometries, intricate circuit paths, and innovative product designs.

Reduced Size and Weight

Elimination of fasteners and connectors, combined with the strategic use of lightweight materials, results in smaller and more compact designs.

Increased Reliability

Inserts securely encapsulated within the plastic matrix ensure improved resistance to shock, vibration, and environmental factors, ensuring long-lasting performance.

High-Quality Solutions

Precision

Exacting precision in every molded part, ensuring high-quality results.

Innovation

Continuous innovation in materials and processes to deliver cutting-edge solutions.

Efficiency

Streamlined processes for efficient production and cost-effective solutions.

Unlock New Possibilities

Enhanced Performance

Unlock new possibilities for your products with enhanced performance and durability.

Cost-Effective Solutions

Explore cost-effective solutions that meet the demanding requirements of diverse industries.

Innovative Designs

Realize innovative product designs, intricate circuit paths, and complex geometries with insert molding technology.