Over-Molding at Yomura

Learn about Yomura's expertise in over-molding and the advantages of this precision manufacturing process in creating high-quality, durable products.

CONTACT USOver-Molding Process

What is Over-molding?

Over-molding is a precision manufacturing process in which one material is molded over another material, typically rubber or thermoplastic elastomer (TPE) over plastic. This process is often employed when the design requires a "soft touch" or waterproofing (IP68) feature.

Insert Molding

Insert molding can also be combined with over-molding, incorporating materials such as aluminum, brass, stainless steel, copper, plastic, and more.

International Protection Rating IP-68

IP-68 is the most rigorous Ingress Protection classification for water and dust protection. Products rated IP-68 have undergone stringent testing in certified laboratories, proving their ability to provide complete protection against long-term submersion under water.

Materials

TPE Materials

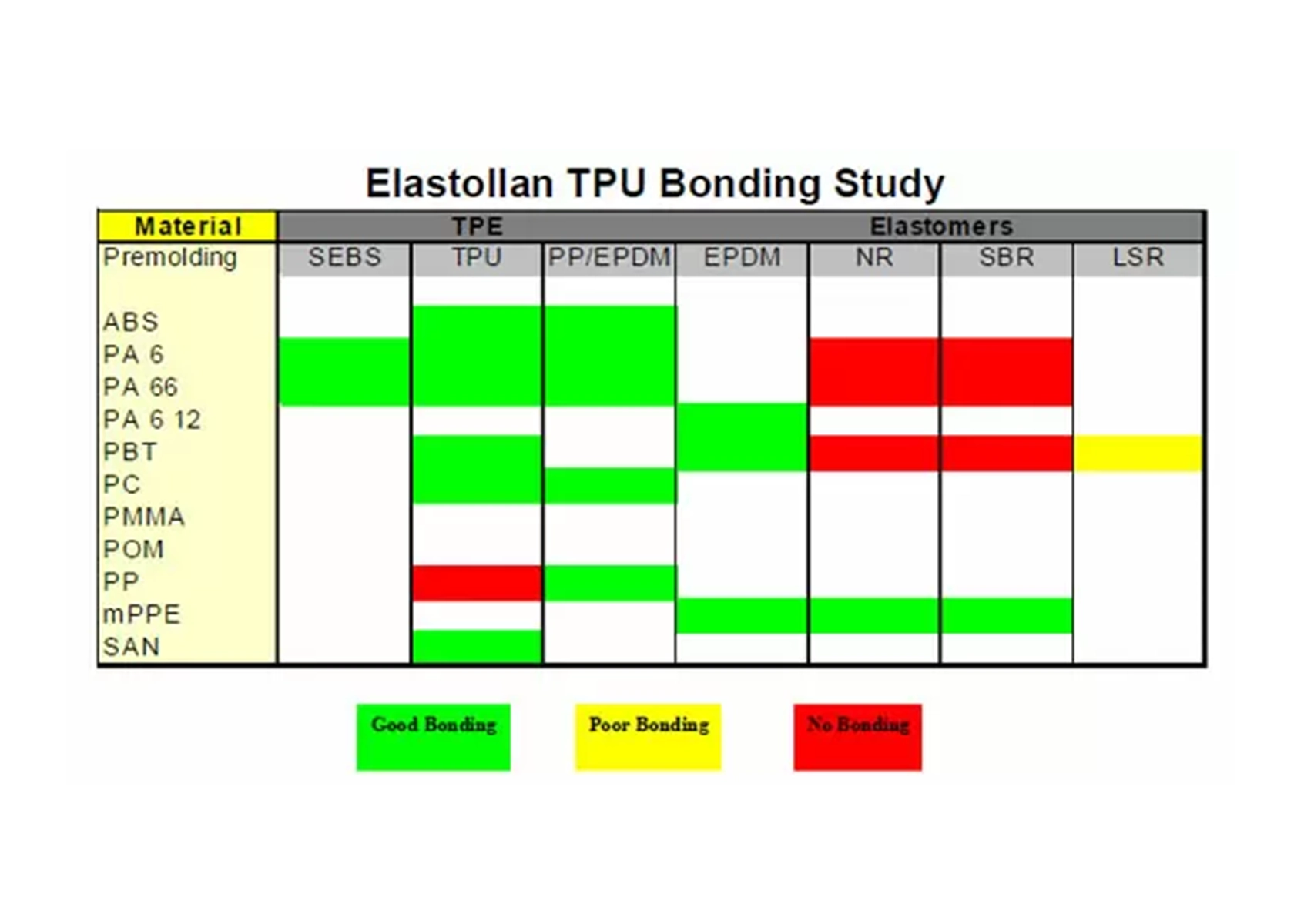

Over-molding of thermoplastic elastomers (TPEs) is a specialized process, and our TPE materials are carefully formulated to bond with a variety of thermoplastics.

Materia Compatibility

- PC/ABS, PC/PETG, Acetal (POM)

- Copolyester, Polystyrene (PS)

- Polycarbonate (PC), Polyphenylene oxide (PPO)

- High Impact Polystyrene (HIPS)

- Acrylonitrile Butadiene Styrene (ABS)

- Standard and Modified Nylon 6, Nylon 6/6, Nylon 6,6,6

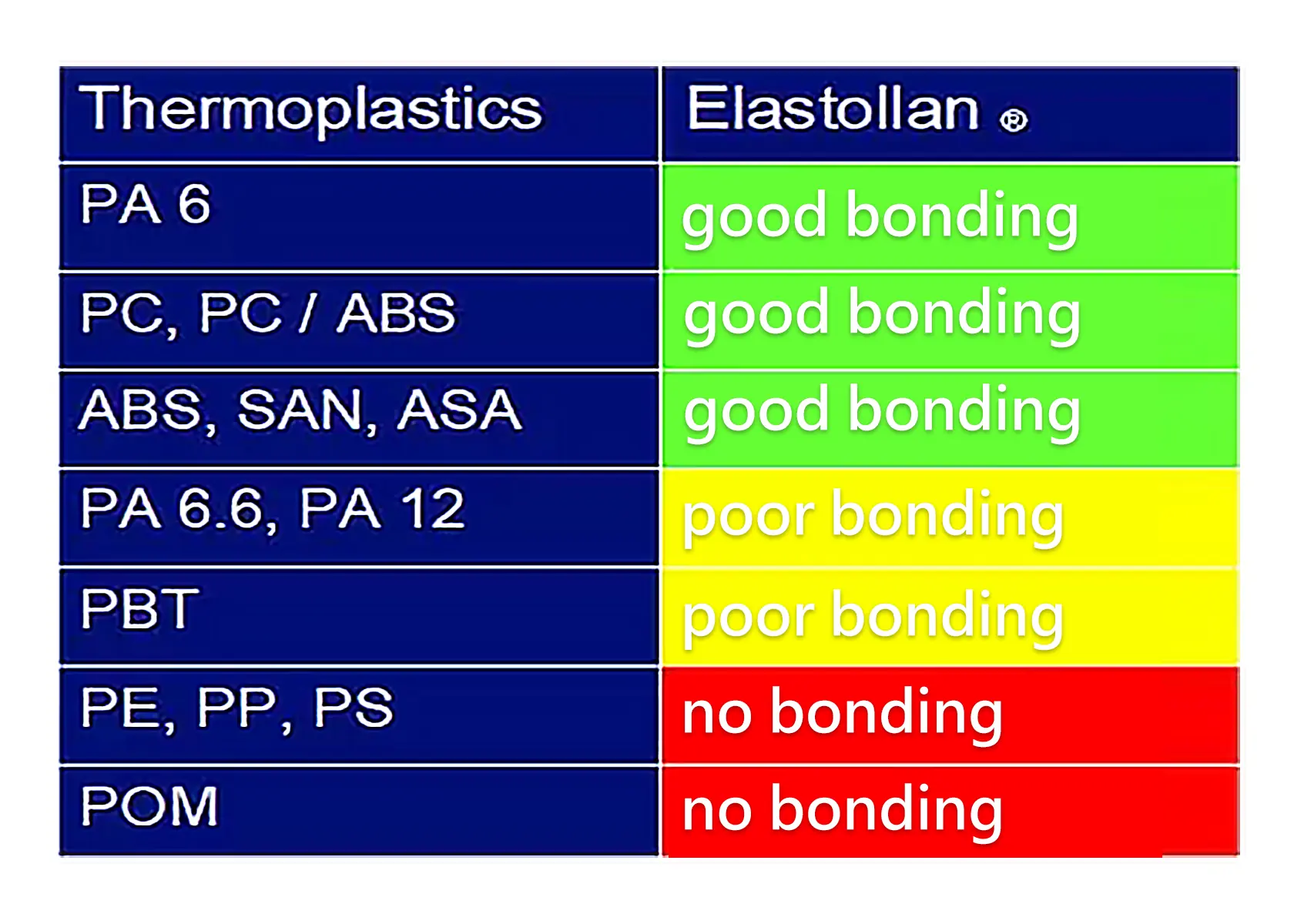

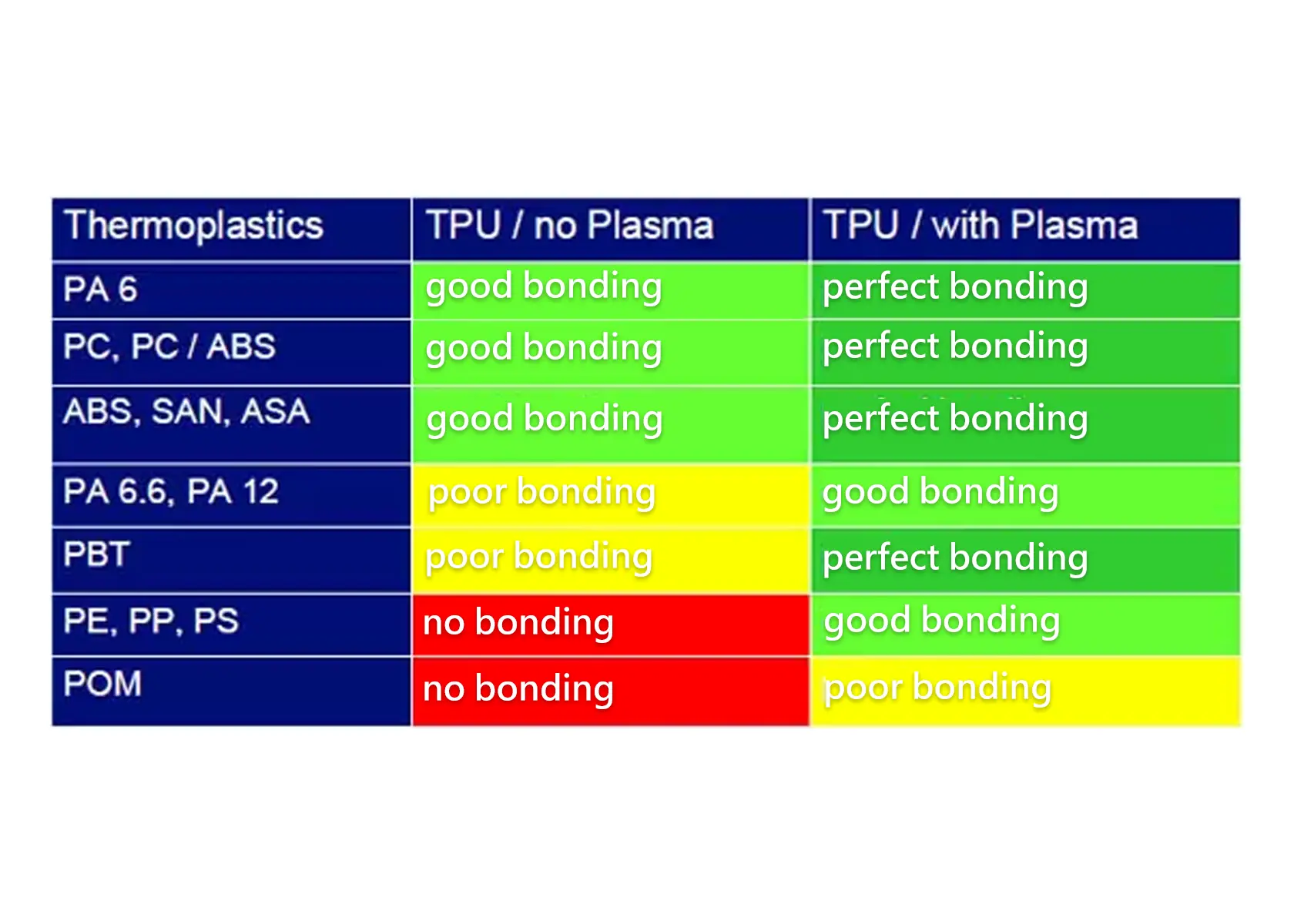

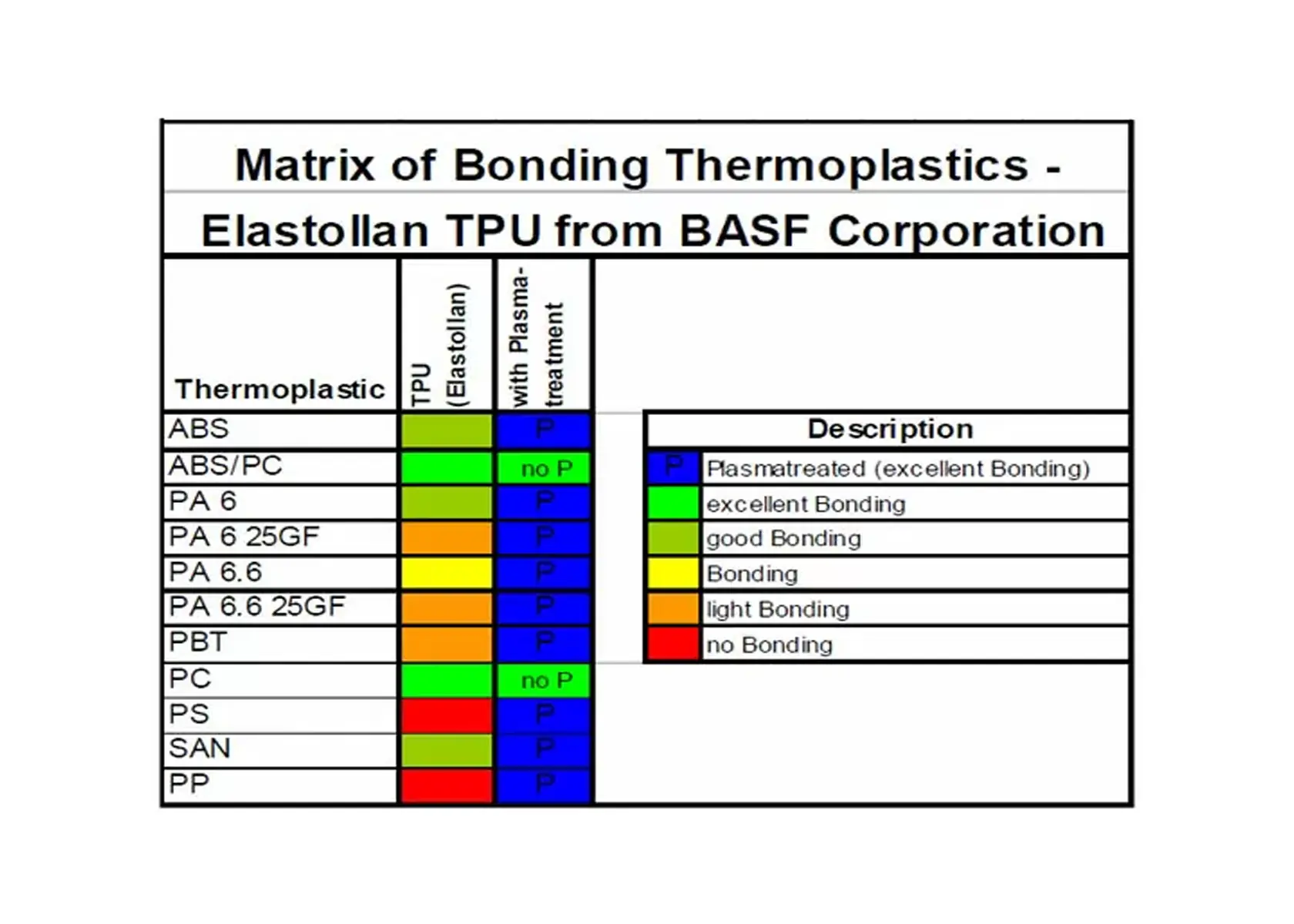

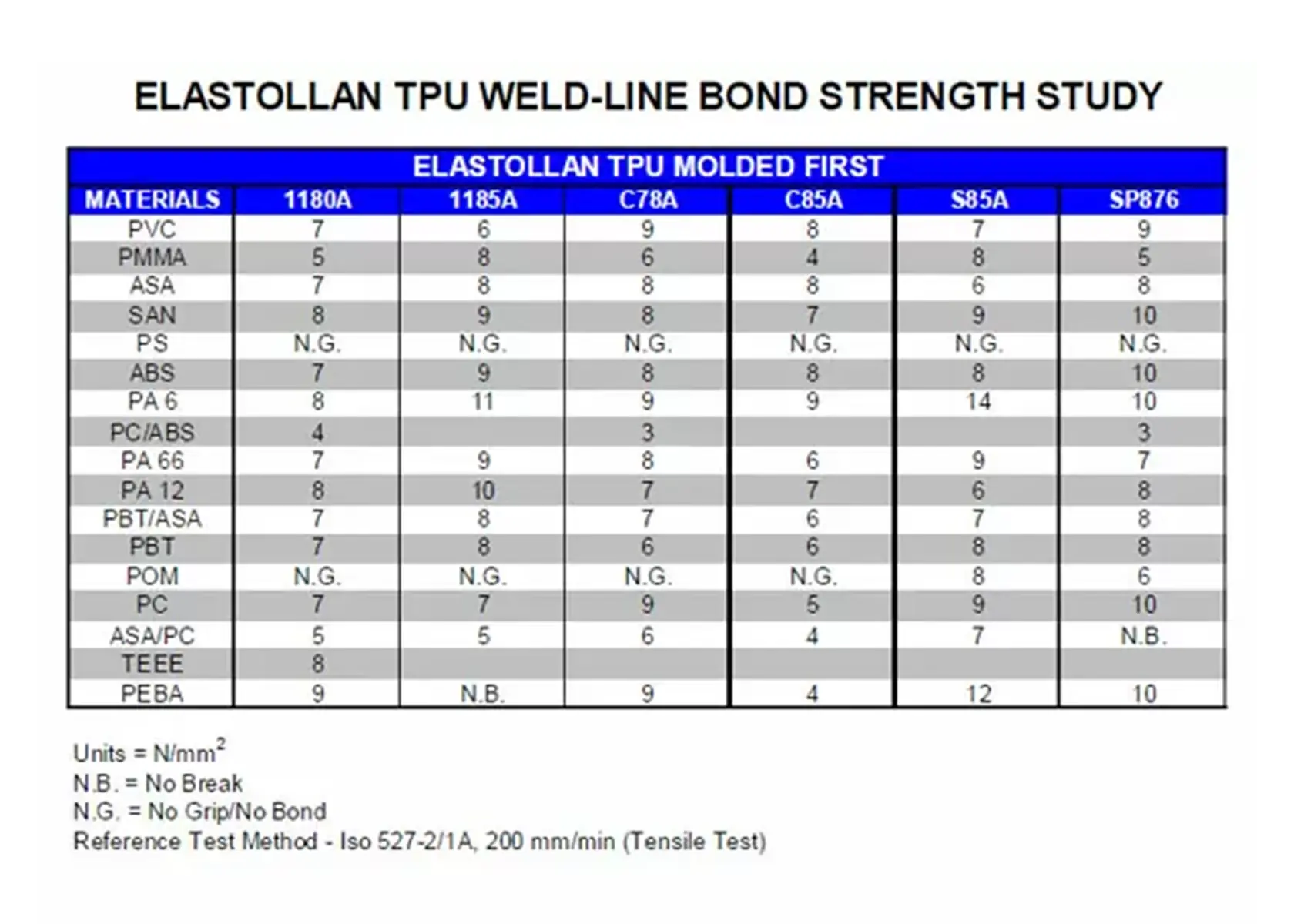

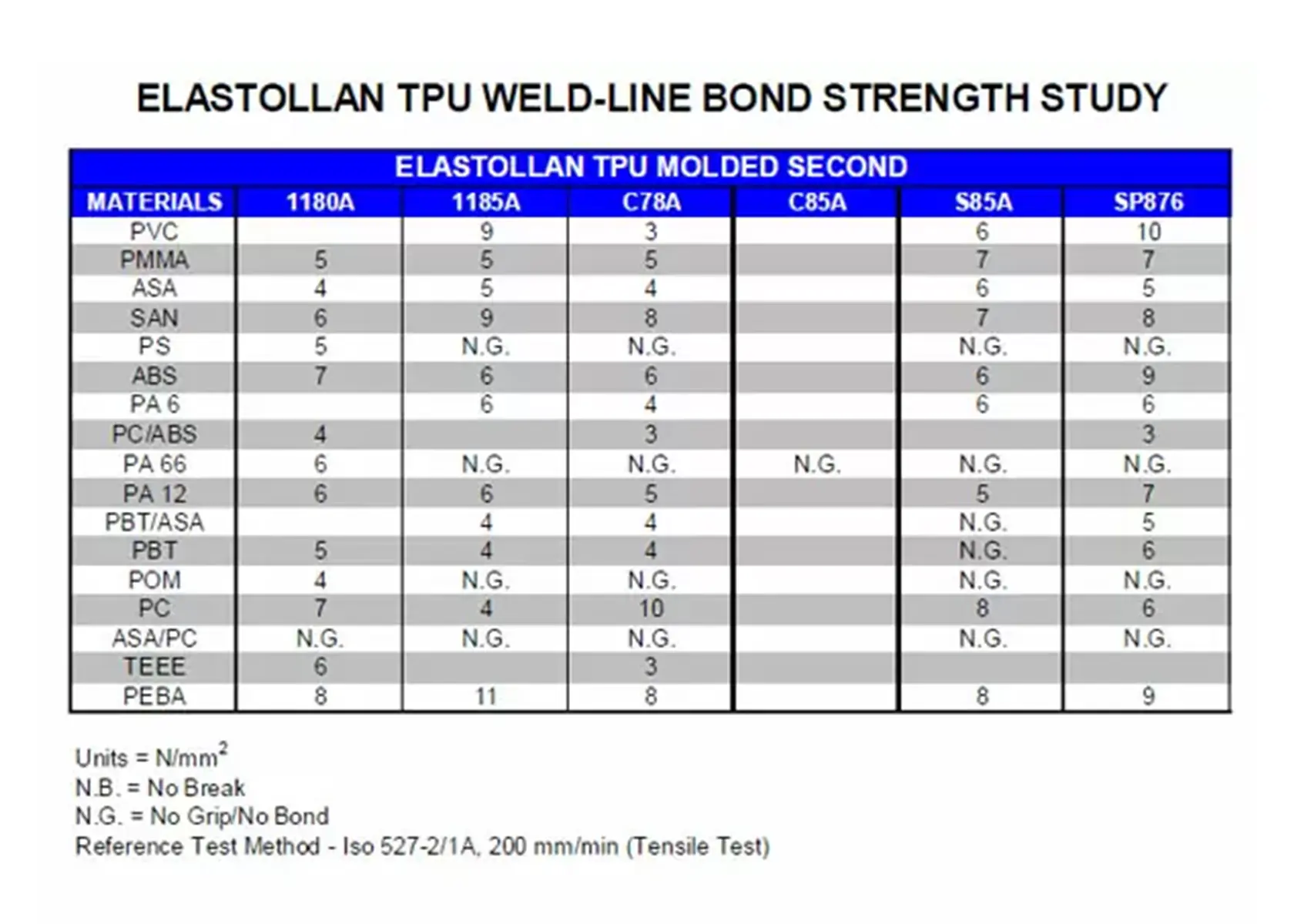

Material Reference Charts

Advantages

Easy to Grip, Soft Touch Feeling

Over-molded TPE surfaces provide a comfortable and ergonomic grip with a soft-touch sensation.

Flexibility and Hinge Capabilities

TPE over-molding allows for flexible components, making it suitable for hinges and other dynamic applications.

Expanded Design Versatility

The integration of multiple materials through over-molding enables greater design flexibility.

Applications

Handheld Portable Housings

Over-molded products are used in hand-held device housings for enhanced durability and a comfortable grip.

Medical and Industrial Parts

Over-molded components are vital in medical equipment and various industrial applications to ensure reliable performance.

Sports and Leisure Equipment

Over-molded parts are utilized in sports and leisure equipment for enhanced durability and impact resistance.

Drop Protection and Shock Absorption

Impact Resistance

Over-molded TPE enhances impact resistance and shock absorption capabilities, ensuring product durability.

Reduced Part Size

Over-molding eliminates the need for additional assemblies, contributing to smaller and lighter end-products.

Reduced Assembly Time and Cost

Streamlined Manufacturing Process

Over-molding simplifies the manufacturing process, reducing assembly time and associated costs.

Improved Product Accuracy

The precision of the over-molding process ensures precise alignment and reliable performance of the finished product.

Yomura's Expertise

Extensive Knowledge

Yomura leverages extensive knowledge of material compatibility and over-molding techniques to deliver high-quality, durable, and functional products tailored to specific requirements.

Exceptional Design Integration

Our expertise ensures the successful integration of materials and strong end-application bonds for optimal product performance.