Double Injection Molding Excellence by YOMURA

YOMURA TECHNOLOGIES: Unmatched precision in creating complex, multi-material components with superb craftsmanship and innovative double injection molding expertise.

CONTACT USUnderstanding Double Injection Molding

What is Double Injection Molding?

How It Works

Materials Used

Advantages of Double Injection Molding

Multi-Material Mastery

Create components with unique characteristics by combining hard and soft materials, resulting in exceptional quality and distinct functionalities.

Durable Bonds

Molecular co-polymerization provides unmatched strength, ensuring the long-lasting integrity of your products through rigorous usage.

Creative Freedom

Design with innovation. Embrace a wide array of design possibilities and incorporate features that set your products apart.

Streamlined Cost-Efficiency

Reduce assembly costs and minimize defects with a process that integrates components into a single, perfected piece.

Enhanced Design and Aesthetics

Captivating Visuals

Our advanced molding process allows for vibrant, eye-catching components that enhance visual and tactile enjoyment, elevating user experience.

Color and Texture

Combine various resins to create rich textures and colors, offering a sensory advantage that makes your products stand out.

Form Meets Function

Not just aesthetically superior, our molding techniques ensure your components serve their purpose with added distinction and market appeal.

Custom Engineering Solutions

Design Optimization

Collaborative efforts between engineers and customers refine designs for optimal product performance and manufacturing efficiency.

Material Selection

Choose from a vast selection of suitable materials, guided by YOMURA's profound expertise to meet your unique application needs.

Innovation & Techniques

Implementing cutting-edge manufacturing techniques, our team transforms innovative concepts into tangible, high-quality solutions.

Double Injection Molding Applications

Consumer Electronics

From ergonomic gadgets to wearables, YOMURA is instrumental in producing intrinsically designed parts for the tech-savvy consumer.

Automotive Excellence

Robust and elegant, our automotive components meet high-performance standards while contributing to luxurious aesthetics.

Medical Innovations

Ensuring safety and precision, we mold medical components that exceed expectations in functionality and reliability.

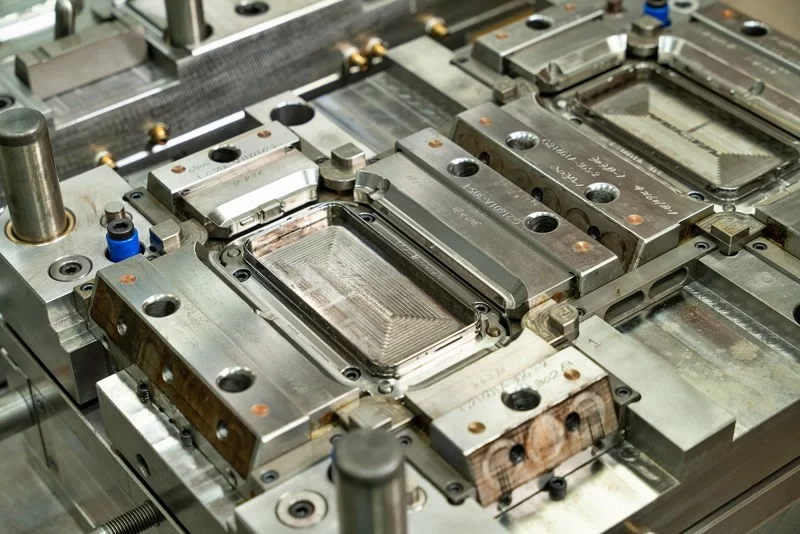

In-House Mold Manufacturing

Customized Molds

Our in-house mold making capabilities allow us to create bespoke molds tailored to the exact needs of each project, resulting in perfect fits and impeccable quality.

Streamlined Production

Maintaining control over the entire manufacturing process from mold creation to part production ensures efficiency and a rapid turnaround for our clients.

Maintenance & Care

Rigorous maintenance practices guarantee the longevity and precision of our molds, contributing to the sustainability of our operations and products.

Quality Control and Assurance

| item | describe |

|---|---|

| Automated Inspections | Use of advanced optical inspection systems for consistent quality checks on every component produced. |

| Meticulous Testing | Rigorous physical and performance testing procedures to verify the integrity and longevity of our products. |

| Certified Standards | YOMURA adheres to international quality standards, including ISO certifications, ensuring global recognition of our products' excellence. |

Partner with YOMURA Today

CONTACT USCollaborative Process

Become a part of our integrated client process, where we work with you from conception to production, ensuring that each step adds value to the final product.

Customized Solutions

Your vision realized through our tailored double injection molding solutions; together, we can turn innovative ideas into market successes.

Global Impact

Join forces with a globally recognized leader in high-precision molding, and make a lasting impact on your industry with YOMURA.