Yomura Rapid Prototyping Solutions

Bringing Your Product to Market Quickly and Cost-Effectively

Contact Us

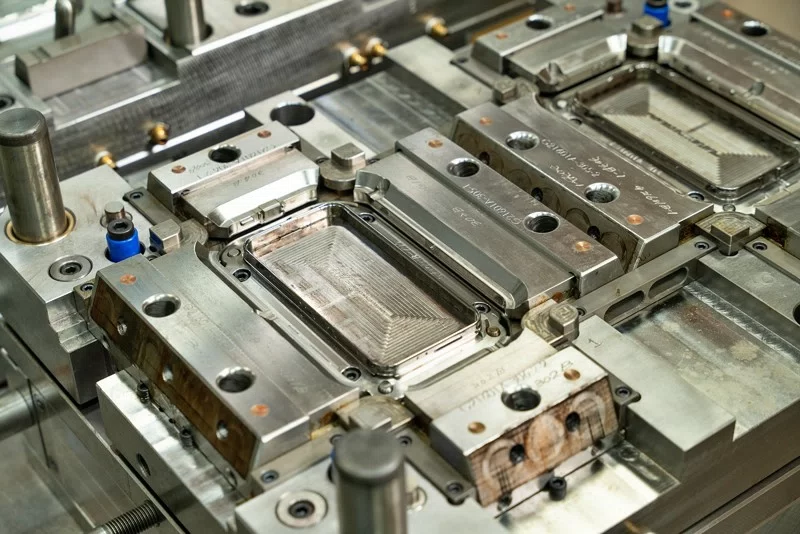

Soft Tooling: Rapid Prototyping and Low-Volume Production

Soft Tooling Expertise

Our engineers received specialized training in Japan from industry experts, ensuring the highest level of knowledge and skills.

Materials and Construction

High-Quality Materials

Cavity and core inserts are made from high-quality aluminum or steel for durability and precision.

Free Mold Base

The mold base is free, allowing for cost-effective production without compromising quality.

Advantages of Soft Tooling

Low Cost and Short Lead Time

Rapid production with lead times ranging from 5 to 10 days at a fraction of the cost of traditional tooling.

Risk Reduction

Ideal for research and development testing, trial runs, and reducing risks associated with final tooling.

Versatility

Soft tooling can produce approximately 500 shots, providing ample opportunity for evaluation and refinement.

Soft Tooling Considerations

Cycle Time

Due to lower thermal conductivity, soft tooling will cycle slower than traditional tooling.

Material Life

Lifespan of soft tooling is limited and dependent on the complexity of the part being produced.

State-of-the-Art Mold Fabrication

Precise Mold Production

Equipped with high-end Charmilles EDM and OKK CNC machines for consistent and precise mold fabrication.