Material Excellence at Yomura

Discover unparalleled reliability and precision in plastic injection molding with Yomura's exceptional material characterization laboratory.

Contact UsState-of-the-Art Testing Equipment

Advanced Analysis

Yomura's lab utilises cutting-edge equipment enabling precise analyses of modern engineering-grade plastics.

Expert Team

Our highly skilled material scientists and technicians are the driving force behind the innovative solutions we provide.

Quality Assurance

Through rigorous testing, we ensure each product meets our exceptional standards, ensuring trust and reliability in our brand.

Comprehensive Material Characterization

Yomura's material characterization laboratory conducts comprehensive analyses on a wide range of engineering-grade plastics. Our highly skilled team of material scientists and technicians meticulously evaluate various material properties, including:

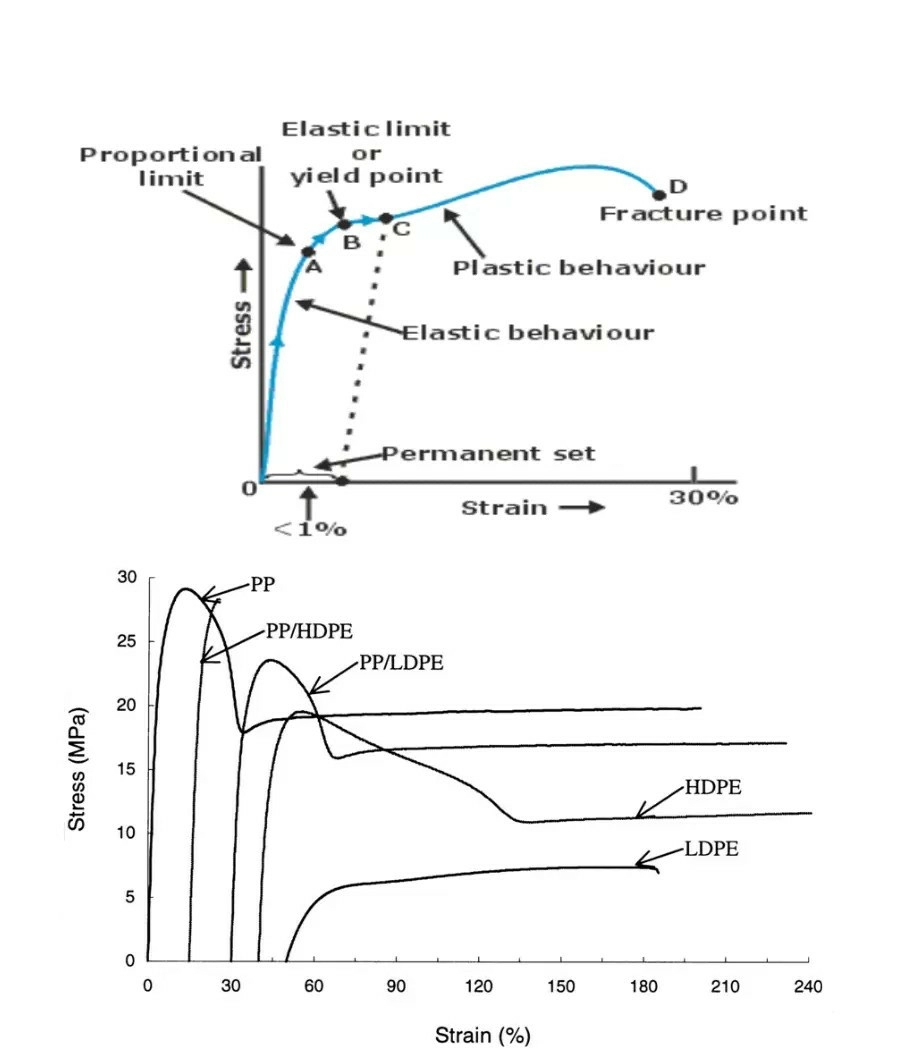

Mechanical Properties

We perform rigorous testing to assess the tensile strength, flexural modulus, impact resistance, and fatigue behavior of materials, ensuring that our products can withstand the demanding conditions of their intended applications.

Thermal Properties

Understanding the thermal characteristics of materials is crucial in the injection molding process. Our lab tests materials for properties such as heat deflection temperature, coefficient of thermal expansion, and thermal conductivity, enabling us to optimize processing parameters and ensure dimensional stability.

Rheological Properties

Rheological properties, including melt flow index, viscosity, and shear behavior, play a critical role in the moldability and flow characteristics of plastics. Our advanced testing equipment allows us to precisely characterize these properties, facilitating efficient and defect-free molding operations.

Chemical Resistance

Depending on the application, our products may be exposed to various chemical environments. Our lab conducts comprehensive chemical resistance testing, ensuring that the materials we use can withstand exposure to specific chemicals without compromising their integrity or performance.

Environmental Aging

To simulate real-world conditions and predict long-term performance, we subject materials to accelerated aging tests, including exposure to UV radiation, elevated temperatures, and moisture. These tests provide valuable insights into material durability and help us make informed decisions regarding material selection and product design.

Optimized Processing Parameters

Mold Design

Leveraging material data to innovate and refine mold designs for optimal performance.

Parameter Tuning

Customizing machine settings to align perfectly with material characteristics.

Efficiency Boost

Increased production efficiency results from precise control over the injection molding process.

Proactive Issue Identification

99.9%

Reliability

Closing in on perfect production with our proactive quality measures.

24/7

Monitoring

Round-the-clock oversight of material performance and production quality.

Trusted Solutions by Yomura

Customization

Tailored solutions designed to meet the unique demands of your application.

Innovation

The synthesis of material science and engineering expertise results in continuous innovation.

Collaboration

Partner with a company committed to supporting your growth and success in the industry.