In-Mold Electronics:

Transforming Product Design

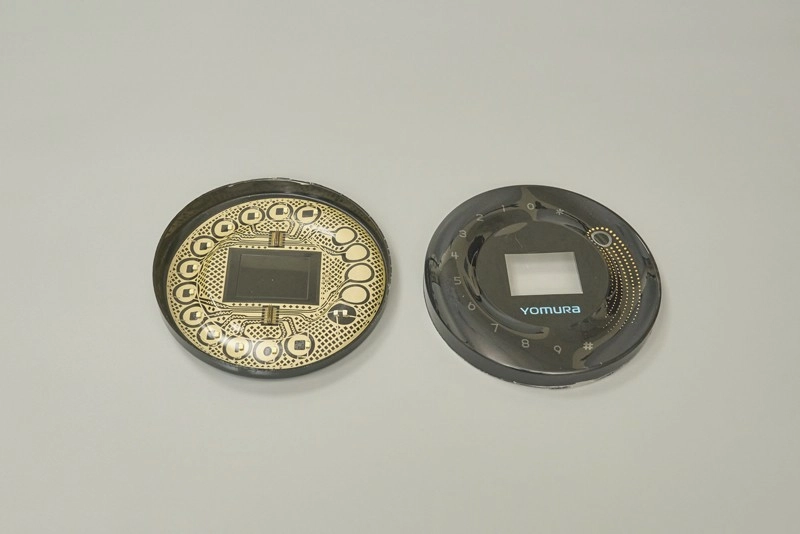

At Yomura, we are revolutionizing product design and functionality with In-Mold Electronics (IME) technology, seamlessly integrating electronics into injection-molded plastic parts.

Contact UsWhy IME?

Safety

Eliminating the need for direct touch interactions, reducing potential hazards.

Power Consumption

Enabling lightweight and compact designs, improving energy efficiency.

Styling

Offering seamless integration of electronics and plastics for sleek, modern aesthetics.

Cleanliness

Providing smooth, seamless surfaces that prevent bacterial growth and simplify cleaning.ing.

The Rise of IME

Embryonic Stage

IME is currently in an embryonic stage, poised for rapid growth between 2023 and 2025.

$1.548 Billion by 2032

Industry analysts estimate the IME output value to reach a staggering $1.548 billion by 2032.

Primary Markets

The automotive industry is expected to be the primary market for IME, followed by white goods and aviation.

The IME Advantages

Traditional Switches

- Bulky and heavy

- Prone to reliability issues

- Thicknesses around 50mm

Membrane Switches

- Eye-catching appearance

- Require multiple components

IME Switches

- All-in-one design

- Thickness of only 3mm

- Up to 93% assembly reduction

- 60-90% thickness reduction

- 40-50% weight reduction

Beyond Surface Decoration

IMR/IMD

IMR (In-Mold Roll) and IMD (In-Mold Decoration) technologies are designed for printing patterns on plastic films.

IME Integration

IME takes integration to a whole new level by embedding electronics into the plastic itself.

Green Transition

Driven by the 2050 net-zero transition and circular economy, the automotive industry is embracing green IME solutions for sustainable product designs.

IME Process Integration

In-mold electronics (IME) is a fusion process that combines several industry manufacturing platforms, allowing Yomura to build technical bridges across different industries and foster agile IME development.

Cross-Industry Collaboration

IME brings together expertise from multiple manufacturing sectors.

Technical Bridges

Yomura facilitates the integration of diverse technologies for IME.

Agile Development

The cross-industry approach enables rapid iteration and innovation.

Overcoming IME Challenges

Yomura's expertise in IME enables us to address unique challenges:

| Challenge | Description |

|---|---|

| Circuit Deformation | Preventing deformation after thermal forming |

| Material Mismatches | Avoiding delamination due to incompatible materials |

| Tombstone Effect | Preventing SMD components from lifting on free-form surfaces |

| Reliability Concerns | Ensuring long-term durability and performance |

IME Core Technologies at Yomura

Design Platform

- Materials database, process parameters, and structural design for automation

- Simulation and compensation for substrate forming, circuit deformation, and 3D SMD stress

- Graphical User Interface (GUI) for user-friendly IME design

Process Integration Platform

- Material matching for compatibility

- Conformal equipment selection

- Process integration to transition from planar to free-form surface structures

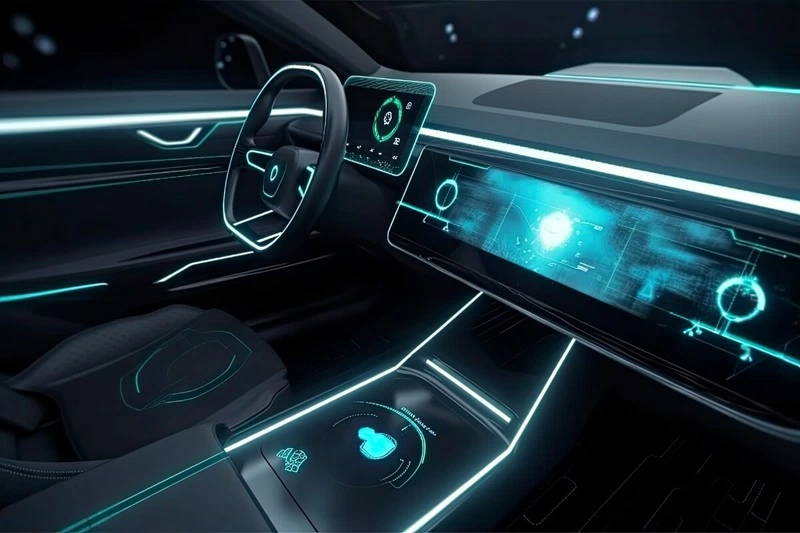

Transforming Car Windows with IME

In-Mold Electronics (IME) is revolutionizing car windows, turning them into interactive displays that enhance the driving experience. Yomura's cutting-edge IME solutions seamlessly integrate electronics into windows, enabling features like navigation, infotainment, and privacy controls.

Advantages of IME for Car Windows

- Seamless Integration: IME creates a sleek, unobtrusive design that blends with the vehicle's interior.

- Enhanced Functionality: Drivers and passengers can access information and controls without compromising their view.

- Durability and Reliability: IME-enabled windows withstand harsh conditions for long-lasting performance.

- Customization: Automakers can create unique, personalized displays that align with their brand.

Yomura's IME Expertise

Yomura's team of experts works closely with automakers to develop tailored IME solutions that meet industry standards for quality and safety.

Key IME Applications

- Navigation and Infotainment: Integrate systems for maps, media, and vehicle settings.

- Augmented Reality: Overlay virtual information onto the real-world view.

- Privacy and Sunshade Control: Adjust tint and opacity with touch or voice commands.

IME technology is transforming the driving and passenger experience, and Yomura is at the forefront of this revolution.

IME Capabilities at Yomura

Design for IME (DFIME)

Collaborate for optimal integration of electronics and plastics.

Component Selection and Sourcing

Aid in selecting suitable electronic components.

Precision Placement

Advanced equipment for precise alignment.

Overmolding and Encapsulation

Specialized techniques for durable products.

Testing and Validation

Rigorous processes ensure reliability.

Global Reach

leverage existing network to provide IME solutions worldwide.

Unlock the Future with Yomura

At Yomura, we understand that IME is more than just a manufacturing process; it's a catalyst for innovation. Our team works closely with you to bring your product visions to life by seamlessly integrating electronics into molded parts.

Enhance Existing Designs

Leverage our IME capabilities to improve upon your current products, adding new functionality and sleek integration.

Explore New Concepts

Partner with us to develop groundbreaking product ideas that were previously impossible without IME technology.

Get Started with IME