Electronic Manufacturing Services (EMS) At Yomura

Providing comprehensive Electronic Manufacturing Services (EMS) to support Original Equipment Manufacturers (OEMs) throughout the product life cycle. From co-design to testing, manufacturing, distribution, and repair services, we are the trusted partner for reliable and innovative solutions that meet unique requirements.

CONTACT USContract Assembly Levels

Our expertise spans a wide range of contract assembly levels, from high-volume, complex electro-mechanical assembly and testing to small-volume, conceptual prototype runs. For small to medium device assembly, we employ a cost-effective system of mobile workstations and conveyors, enabling us to quickly configure secure and private assembly cells tailored to our clients' needs.

Manufacturing Capabilities

Electromechanical Assembly

We specialize in the efficient and precise assembly of electromechanical components, ensuring high-quality end products for our clients.

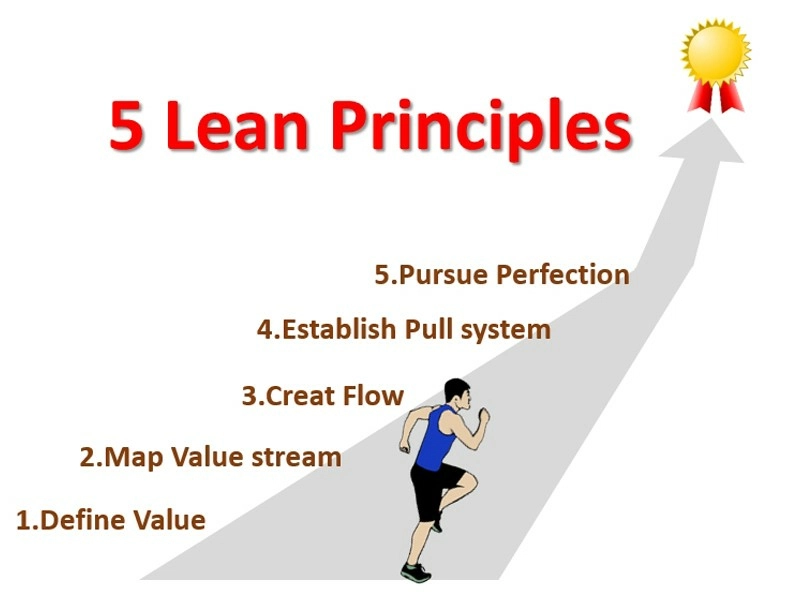

Lean Manufacturing Process

Our Lean Manufacturing PLM, MES, QMS Systems ensure optimized production and efficient resource utilization for cost-effective manufacturing.

Functional And Post-Assembly Testing

Thorough testing procedures guarantee the reliability and performance of our assembled products, meeting the highest industry standards.

Facilities And Production Capabilities

Clean Rooms

Our facilities include 10,000 & 100,000 class clean rooms to ensure the highest standards of cleanliness and product integrity.

Flexible Cell Production System

We employ a flexible cell production system to cater to a diverse range of manufacturing requirements with precision and efficiency.

24/7 Operations

Our operations run around the clock, ensuring rapid response and timely delivery to meet our clients' demands.

Supply Chain Management Services

Material And Component Sourcing

Extensive experience in material and component sourcing helping us provide high-quality, volume products without the risk of high inventory levels.

Streamlined Processes

Our office is designed to streamline processes, providing quick quotes, constant updates, and comprehensive data tracking for seamless communication.

Test Engineering And Rework Services

Test Engineering

Our Test Engineering department is staffed with experienced engineers and technicians who excel at collaborating with customers to develop methodologies and design fixtures to reduce overall manufacturing costs, improve production yields, and support root cause analysis.

Rework Services

Our rework specialists ensure that product assemblies meet the highest quality standards, addressing design flaws, upgrading components, and implementing cost-down solutions as necessary.

Certifications And Quality System

Industry-Recognized Certifications

Our commitment to quality is demonstrated through our adherence to industry-recognized certifications, including AS9100, ISO 9001, ISO 14001, ISO 13485, TS 16949, UL Compliance, FDA, and MFi.

Supply Chain Management Services

Unwavering Quality Standards

We hold ourselves to the highest quality standards, ensuring that every product meets the rigorous criteria set by industry-certified organizations.

Industry Expertise And Commitment

CONTACT USMarket Specialization

We have extensive experience in various markets, including consumer electronics, industrial, medical, military, and telecommunications, enabling us to meet diverse industry requirements.

Client Commitment

Our unwavering focus on client satisfaction drives us to provide tailored and innovative electronic manufacturing solutions that exceed expectations.

Continuous Improvement

We are committed to continuous improvement, staying ahead of industry trends and technological advancements to provide cutting-edge solutions to our clients.